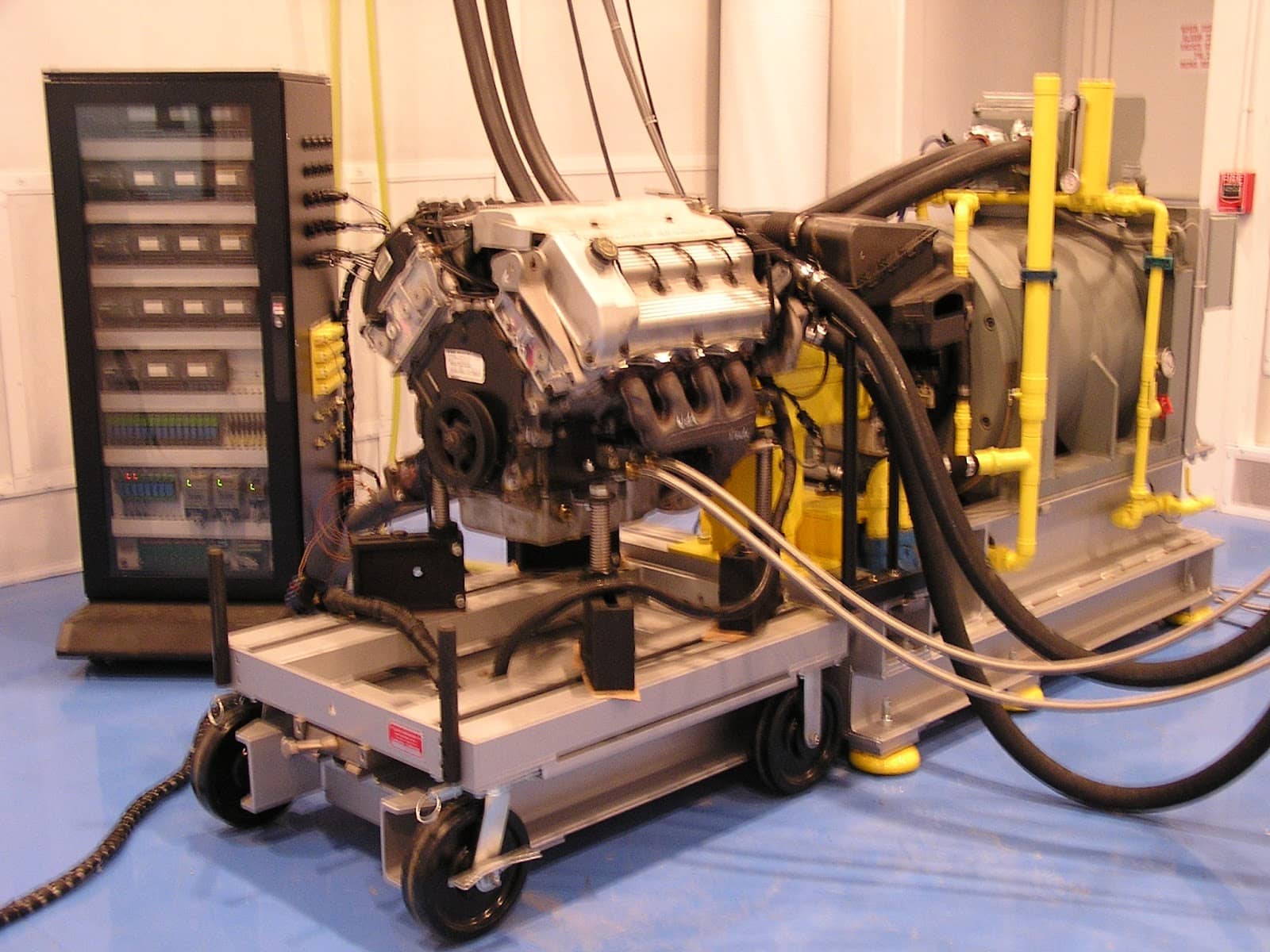

Internal Combustion Engine Dynamometer Test Systems

SAKOR Technologies tailors dynamometer test systems for internal combustion engines of all types

Test Systems for Internal Combustion Engines

With over 35 years of experience, SAKOR Technologies has engineered a wide variety of test systems for internal combustion (IC) engines. We have built dynamometer systems to evaluate innovative IC engines that push the limits of current technology, such as spark-assisted diesel/biofuel engines and those with unique geometries , to standard engines used in everyday applications. We provide dynamometers, test cell controls, and ancillary test equipment to evaluate the performance, durability and quality of all types of combustion engines and their components. Our systems are equally at home running all types of testing, from design validation, to 24/7 unattended durability cycles, end-of-line quality control (QC) testing, to Off-Road Heavy Duty Diesel Transient cycles for emissions certification. We also provide dynamometer systems designed to test specific engine and drivetrain components, such as starters, alternators, transmissions, transfer cases, fuel pumps, power steering systems, emissions control systems and more. Whether you are looking for a reliable, repeatable test cell to validate your products before they hit the market, or you are looking for innovative testing systems to solve cutting-edge industry challenges, our team is ready to help.

We have developed a wide range of test systems for combustion engines, including multiple systems in all of the areas listed below:

- On- and off-road gasoline and diesel engine test systems to perform design validation, performance, durability, and emissions testing.

- Transmission test systems (manual, automatic, continuously variable transmission)

- Transfer case and automatic clutch systems

- Emissions test systems (exhaust and evaporative)

- Stands for testing individual engine components

Dynamometer Test Systems for Internal Combustion Engines

To design and build dynamometer test systems for internal combustion (IC) engines, we combine our decades of expertise in engineering, physics, and chemistry. This gives us a deep understanding of the individual systems and components that drive IC engines, and allows us to develop the best testing mechanisms for specific applications. Our test cells use modular, extensible products and components that will meet your current objectives and support future growth and change.

Highly Flexible

With flexible power, speed and torque ratings, and a variety of engine and inertia simulation options, our dynamometer test systems are able to perform the tests that you need, when you need them.

Innovative

Innovation starts with tailored dynamometers and the DynoLAB™ GenV test automation system, creating testing solutions that are sophisticated and powerful, yet accessible.

Ready to Run

We work closely with you to design a factory acceptance test that meets your end use goals. With this test performed prior to shipment, we make sure your system is ready to run when it arrives at your location.

Featured Projects

Heavy Duty Off-Road Transient Emissions Test Cell

SAKOR designed a test cell for the United States Department of Energy ReFuel Laboratory in Denver, which performs heavy-duty diesel transient emissions testing for all…

The Optimal Solution

Our goal is to design and configure a test cell that works best for you. To do this, we work with a variety of dynamometer technologies. We configure test systems for IC engines based on your end use goals. This means the system is tested before integration with your facility and products, so it fits perfectly. We don’t ship products out of a catalogue; we engineer reliable, adaptable solutions using the best technology available.

Our dynamometer systems for combustion engines may include:

- AC motoring dynos

- Eddy current dynos

- Water brake dynos

- Tandem brake and motor dynos

- Hysteresis brake dynos

Adaptable and Highly Efficient

SAKOR has responded to the increase in demand for motoring dynamometers by developing the AccuDyne™ line of AC Motoring Dynamometes, which can provide true simulation of real-world, in-use events, including road-load profiles. With a broad range of power, speed and torque ratings, the AccuDyne™ makes it easy to simulate varying conditions and events, and ensure your products perform as needed. In addition, the AccuDyne™ system is fully line regenerative, greatly reducing electrical power consumption and therefore cost of operation.

The system can:

- Integrate with a wide range of testing instrumentation to provide a full range of testing options, including design validation, performance testing, durability testing, road load simulations, fuel economy, emissions testing and more.

- Interface with automation equipment and controls for continuous testing with minimal oversight.

- Evaluate the performance, durability and quality of a wide range of internal combustion engine types and components, from high-performance racing engines, heavy-duty industrial engines, automotive engines, consumer products and more.

Our Systems Delivery Process

The SAKOR delivery process is different from the competition. We don’t ship products out of a catalogue; we work closely with you to understand your products and tailor a solution that is guaranteed to work at your facility. From engineering through testing to set-up, we are only a phone call away and ready to answer your questions or concerns. Learn more about our process ›

Contact SAKOR

SAKOR is your best option for combustion engine dynamometer systems that are accurate, durable, and designed for the future. Over the past 35 years, we have delivered hundreds of systems to leading manufacturers of combustion engines, testing laboratories, regulatory agencies, and engine technology innovators. Let’s have a conversation to see if we can help you out with your next project.