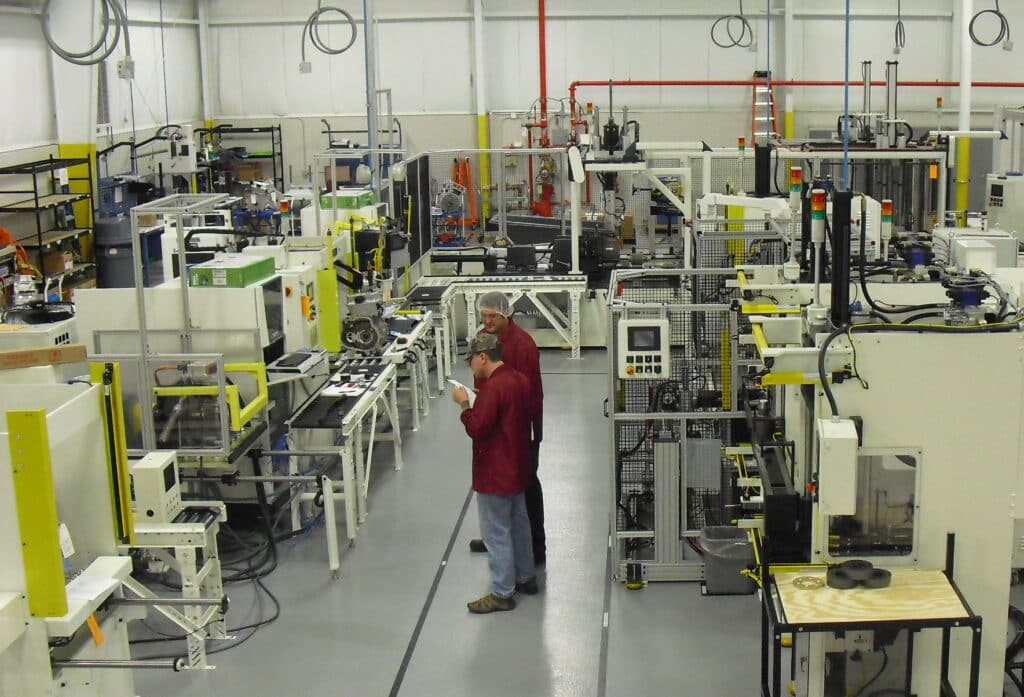

Electric Vehicle Motor/Inverter Production Testing System

Project Type: Electric Vehicle Motor/Inverter Production Testing System

Customer: Magna Electronics, Holly, MI

Dynamometer: 100 kW AccuDyne AC Motoring Dynamometer

Control System: DynoLAB

Other Equipment: 100 kW high-voltage battery simulator, high-bandwidth electric power analyzer, Hi-Pot unit, precision resistance meter

This multi-station test system, with test stations at different points of the assembly line, interfaces with the automated assembly line controls, tests the sub-assemblies and gathers relevant parameters. It then accepts completed motor/inverter units, flashes previously gathered parameters to the unit’s ECU, and then performs a full load performance run on 100% of all production units. The system also performs fully automated coolant filling and draining as well as coolant system leak checks during testing.